Microscopic and precise

We live in an information-oriented society where globalization and diversification of customer needs are accelerating. Electronics is essential in today’s semiconductor market, and super integrated, high-technology hardware forms the basis of it. The demand for such hardware is ever increasing. To respond to this trend, related systems and parts have been microscopic and microminiaturized, and significant progresses in machining technology and manufacturing systems have been sought. We at FUJIISEIKO Co., Ltd., are responsible for development.

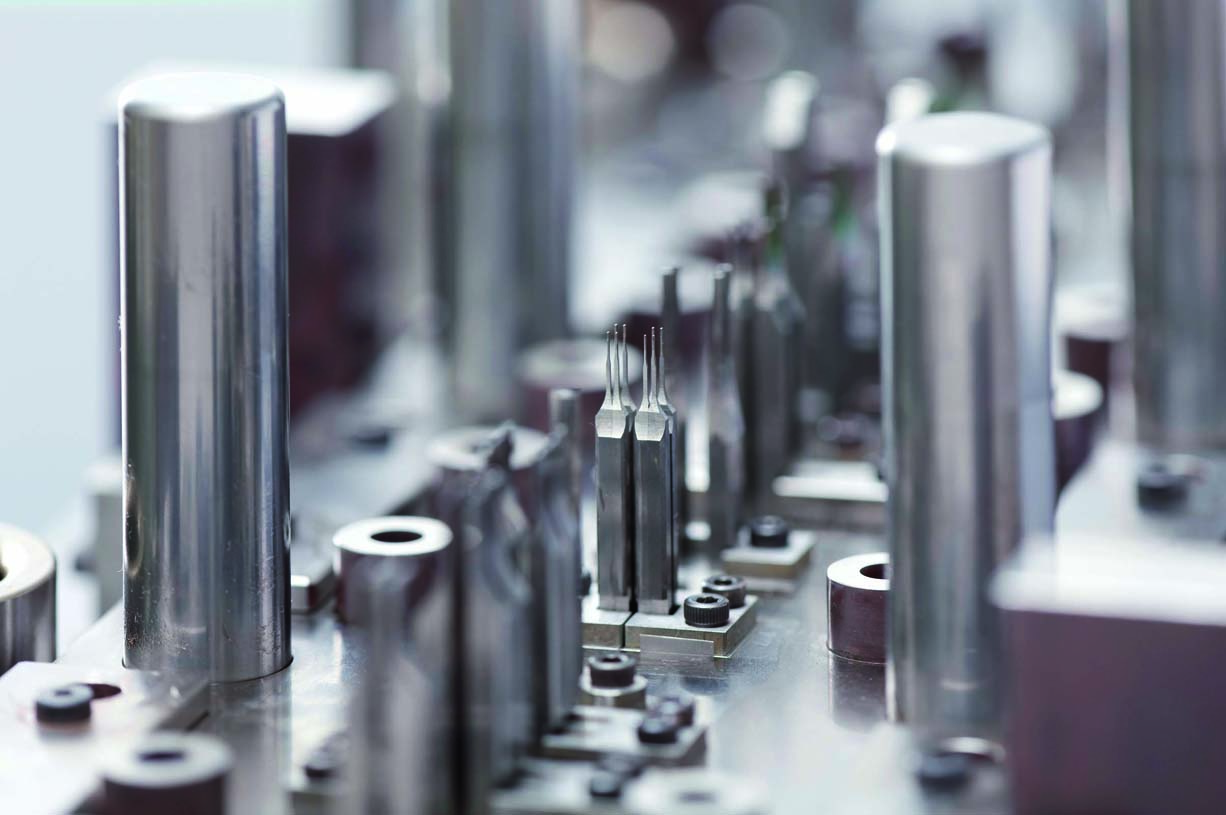

Through our long-accumulated know-how, technical advice tailored to product needs, and design engineers’ reliable techniques, we have manufactured dies that are used to produce super-precision equipment parts with 0.001 mm precision. We have been aiming at more microscopic and precise manufacturing. We aspire to take advantage of the pride of our acquired engineering spirit and our expertise, and pass them onto the next generation.

High-precision product lines as a result of our challenge to ultimate micromachining

Creation from scratch is unmatched pleasure. The principle of our manufacturing is technical advice-based consultation with customers. Our products are a result of the craftsman spirit of our design engineers, which has paved the way for new technologies.

Dies for electrical and electronic parts

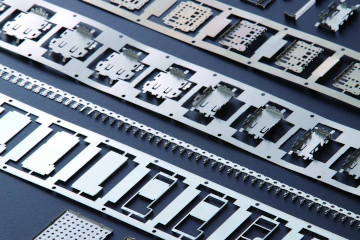

High-precision electrical and electronic parts whose tolerances are accurately controlled with 0.001mm precision.We have a wide range of precise, robust, long-life dies.

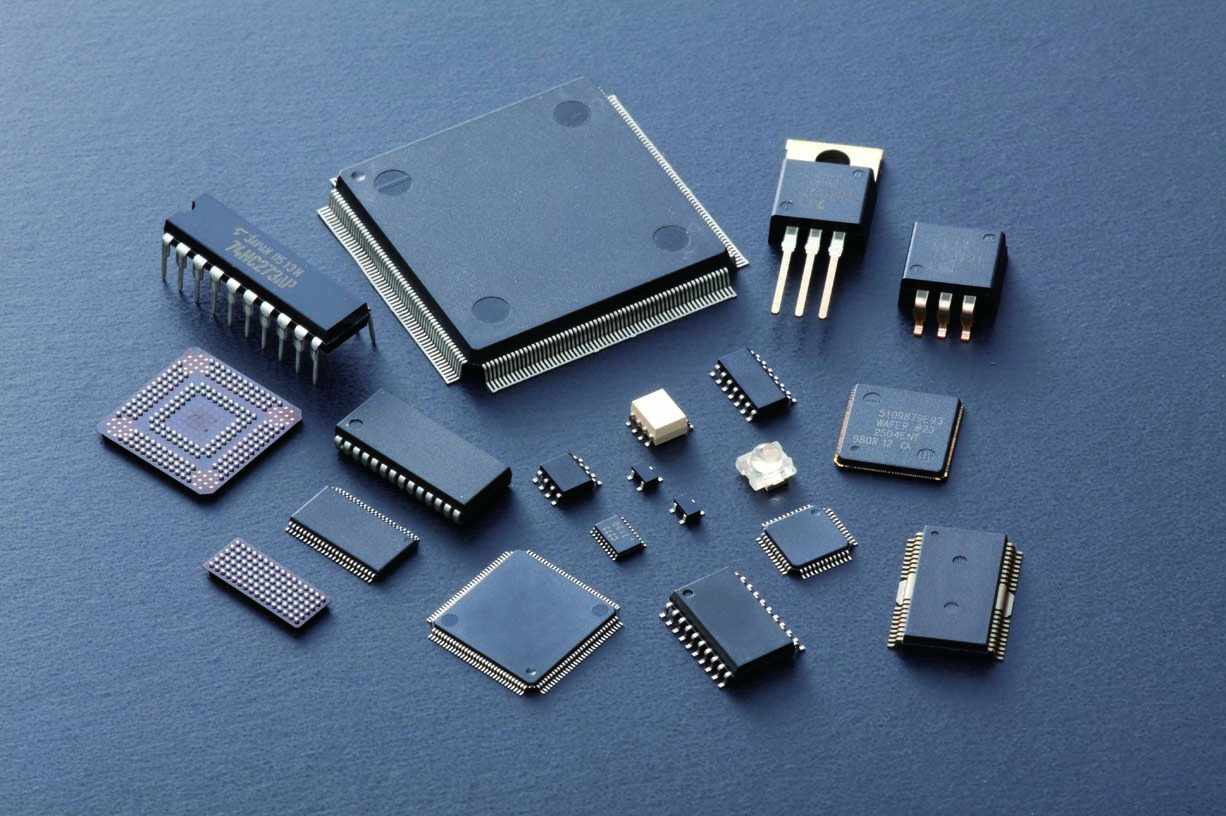

Dies for semiconductors

ICs (integrated circuits) have been diversified by the emergence of various electronics. We manufacture dies with highly heat-dissipative materials.

Dies for motor cores

We can produce stamping dies for different kinds of motor cores.

Stamping dies

We produce stamping dies for manufacturing super-precision parts and narrow-pitch connectors that are incorporated into cutting-edge electronic devices.

High-performance equipment only achieved by a total production maker

We strive to create a manufacutring environment by building a new temperature-controlled plant to achieve high-precision machining, introducing super-precision CNC 3D measuring machines, and taking other actions. Manufacturing high-performance dies is only possible by combining high-precision equipment and the high skills of the technicians who use them.

To provide high-quality products, FUJIISEIKO achieves stable quality control with its long-accumulated know-how and total production system.

FUJIISEIKO is among the quickest makers in the industry, and has acquired ISO 9001 and JIS 09001 certification for all plants. We aim to make highly accurate, perfect dies with tool maker’s microscopes, projectors, digital micrometers and other advanced inspection tools. We ensure high quality through our substantial training system.

From Fukuoka to the World, FUJIISEIKO is playing an active role on the global stage.

To bring happiness to people in today’s global society, we convey the spirit of Japanese manufacturing to the world through our constant efforts to improve technologies.

| Mission statement | Believe all members are the best picked, trust one another, and build a better life based on the idea of coexistence. |

|---|---|

| Management policy | Work with the customer’s viewpoint in mind.Continue developing and improving our technologies.Commit ourselves to attaining stable growth for our company.Make efforts to improve our employees’ quality of life.Provide thorough training for our employees.Our basic management policy is to widely contribute to society by taking these five actions. |

| Overview Company Name | FUJIISEIKO Co., Ltd. |

| Address | 1057 – 1 Muroki, Kurate – machi, Kurate – gun Fukuoka 807 – 1307, Japan |

| Tel | +81- 949- 42- 5651 |

| Fax | +81- 949- 42- 3177 |

| info@fujiiseiko.co.jp | |

| URL | http:// www.fujiiseiko.com/ |

| Capital | 30 million yen |

| Representative | President Fukuyoshi Fujii |

| Foundation | February 26. 1976 |

| Employees | 60 |

| Business Lines | Design and manufacture of precision dies for producing ICs Design and manufacture of trimming and forming equipment for producing ICs Design and manufacture of stamping dies for electric appliances Manufacture of precision parts for dies Design and manufacture of jigs and tools |